Dana 80 Rear Axle Rebuild & Upgrade for Overland and Expedition Trucks

Reliability over everything else - Dana 80

When building a reliable overland vehicle or expedition truck, few components matter more than the rear axle under your rig. Strength, serviceability, and long-range dependability are all critical — especially when you're hundreds of miles from the nearest parts store. For our build, we chose the Dana 80 rear axle, a heavy-duty and proven platform popular in off-road and overlanding communities. Now that it’s in our hands, it’s time to rebuild, modify, and upgrade it to meet the unique demands of life off the grid.

Dana 80 Rear Axle – Overland Rebuild and Mods

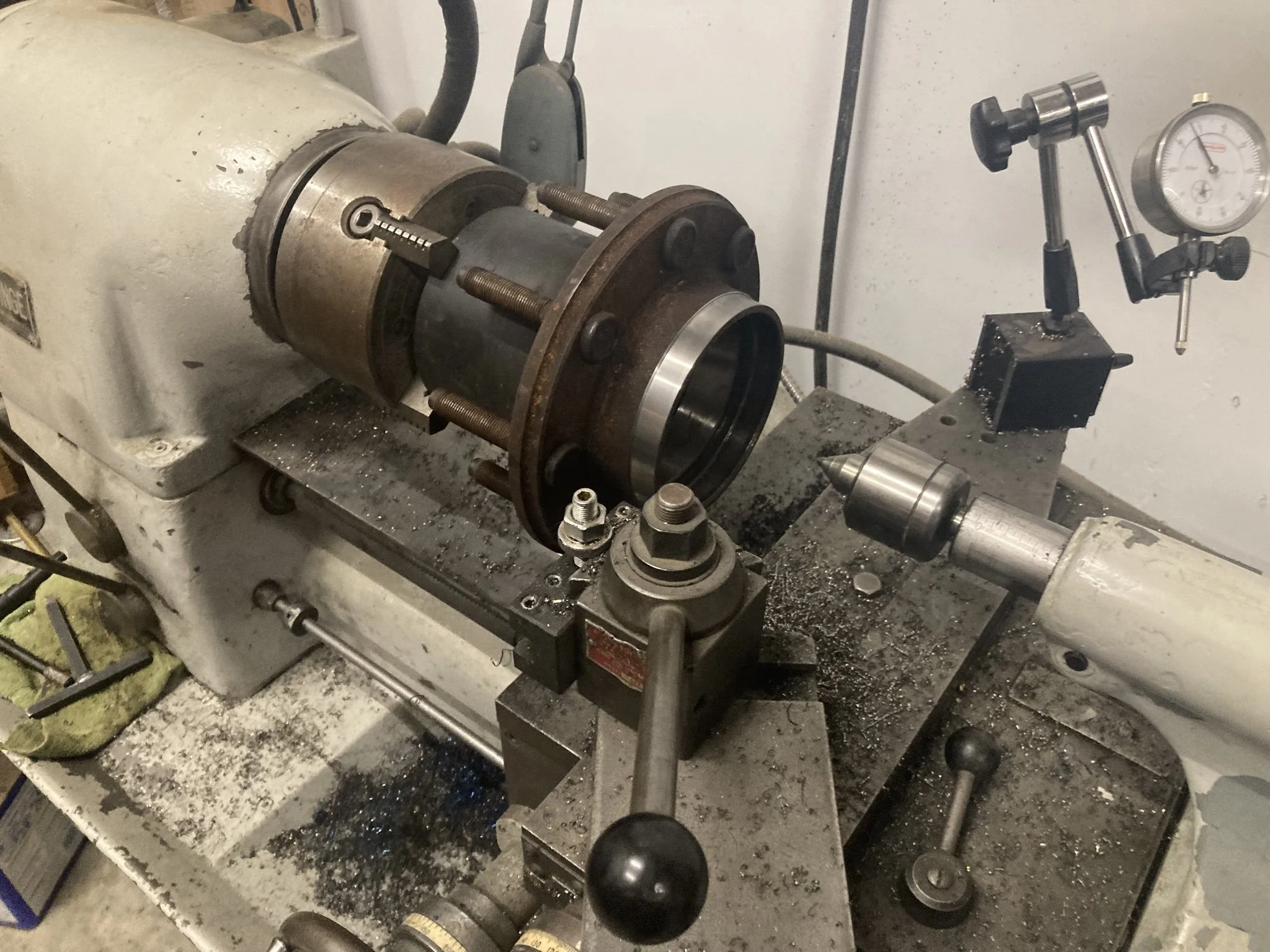

Gearing – For overland trucks running larger tires and heavy loads, proper ring and pinion gear ratios are essential. We upgraded from the factory 3.54:1 to a more suitable 5.38:1 gear ratio to maintain low-end torque and drivability for off-road crawling and loaded highway travel. We carefully set up the gear pattern with precision tools, ensuring a quiet and reliable drivetrain.

Limited Slip Differential – Choosing the right limited slip differential (LSD) is critical for expedition and overland vehicles. The Eaton Truetrac LSD provides reliable torque transfer without complex electronics or air compressors, making it ideal for remote off-road travel where simplicity equals reliability.

ABS Integration – Maintaining factory ABS system compatibility is important for modern trucks. We designed custom ABS tone rings and sensor mounts to ensure the truck’s ABS and traction control systems continue to function correctly after axle modifications.

Hub Nuts – The Dana 80’s factory hub locking nuts are a known weak point, risking wheel bearing failure. We upgraded to Stage 8 X-Lock locking nuts for enhanced durability and peace of mind during extended overland trips where maintenance opportunities are limited.

Shock and Spring Mounts – Custom suspension mounting points were relocated to fit our expedition truck’s frame and optimize suspension geometry for heavy loads and rough terrain.

Full Rebuild – Bearings, seals, and brake components were replaced with high-quality parts. The axle was filled with synthetic 75W-140 gear oil and protected with a cast aluminum Yukon differential cover — both upgrades that improve durability in demanding off-road conditions.

How did it turn out?

An overland rig’s reliability hinges on a solid rear axle, and this Dana 80 axle rebuild and upgrade was built with long-distance travel in mind. After 10,000 miles of hard use over diverse terrain, including off-road trails, mountain passes, and highway miles, we’re ready to share a full real-world review of the Dana 80 axle’s performance, reliability, and durability in expedition scenarios.

Stay tuned for the next post to get all the insights, lessons learned, and tips for anyone considering a Dana 80 axle upgrade for their overland or expedition build.