DIY Overland Build: Dana 60 Axle Rebuild, Gear Ratios & Key Upgrades

Upgrading to a Dana 60 Axle for Overlanding: A DIY Guide

Swapping out your stock 2wd axle for a 4wd solution is a game-changer for any DIY overlander. In our build, we replaced the stock I-beam 2WD axle with a robust Dana 60 front axle from a mid-‘80s GM K30 truck. While the Dana 60 is known for its legendary strength and reliability, we knew we could make it even better for our demanding needs. Here’s how we rebuilt the axle from hub to hub, addressing common weak points and making the necessary upgrades to ensure it’s ready for years of adventure.

Why the Dana 60? The Best Axle for Overlanding? We think so!

The Dana 60 is a powerhouse in the off-roading world, well-known for its durability and ability to withstand heavy loads and extreme conditions. While it comes strong from the factory, it’s important to customize it for your specific needs. Whether you’re navigating rocky trails or camping in remote locations, we rebuilt our Dana 60 from the ground up, replacing all bearings, seals, bolts, gaskets and more to ensure maximum reliability.

Key Upgrades we made for Overlanding: Dana 60 Rebuild Breakdown

Gearing: Choosing the Right Gear Ratio for Overlanding

The stock 4.56 gearing in our Dana 60 axle was fine for general off-road use, but we needed something more suited for our heavy truck and highway transmission. After doing the math and considering our needs, we opted for 5.38 gears, this was the lowest we could feasibly go. This gave us the optimal balance between highway speed and slow off-road crawlability, especially when paired with our long legged 6-speed transmission and NP205 transfer case.

Lockout Hubs: Keeping It Simple with Old-School Technology

Lockout hubs were a common feature on most trucks from the '80s and earlier, and for good reason. These simple devices engage and disengage the wheels from the axle, reducing wear and tear when 4WD is not needed. They add a layer of reliability to your 4WD setup, making them a top choice for overlanders who want a durable, low-maintenance system.

For our build, we replaced the missing and malfunctioning lockout hubs with Yukon Hardcore 35-spline lockout hubs. These are made from 100% steel, with chromoly internals, making them tough enough to handle the heavy-duty demands of overlanding. They are fully trail serviceable and parts are easily ordered.

Stub Shafts: Strengthening Weak Points for long term reliability

One common weak point in the Dana 60 axle is the factory 30-spline stub shafts, which tend to fail under high torque. Since overlanding can sometimes put more stress on your components, we upgraded to 35-spline, 4340 heat-treated chromoly stub shafts. These are far more durable, giving us peace of mind knowing that the axle can handle the rigors of rough trails, heavy loads, and long trips.

Steering: Custom DIY Steering for Precision and Durability

For steering, we used DOM tubing (¼-inch wall) to create a custom tie rod that we could easily adjust for proper toe alignment. A shorted factory drag link, combined with welded threaded inserts and an offset tie rod end, allowed us to link to the Dana 60 king pin cap and steering arm. This custom solution ensures we have precise, reliable steering even under heavy loads and rough conditions.

To optimize steering travel and prevent U-joint binding, we set the steering stops by rotating the wheels lock-to-lock, adjusting until we reached the maximum angle allowed by the U-joint.

Steering Stabilizer: Smooth Ride on Rough Terrain

For added control, we installed a Fox steering stabilizer to minimize feedback and vibrations from the road and trail. The stabilizer was mounted securely with custom brackets welded to the tie rod and axle tube, ensuring full lock-to-lock movement without issues.

Diff Cover: Heavy Duty Protection for Off-Roading

We opted to use the same Yukon Off Road differential cover we installed on the rear axle. It’s a strong, durable cover that protects our differential from rocks and debris while keeping everything clean and functional. It’s an easy yet effective upgrade that adds extra protection to vital components.

Modernizing with ABS: Bringing an Old Axle into the 21st Century

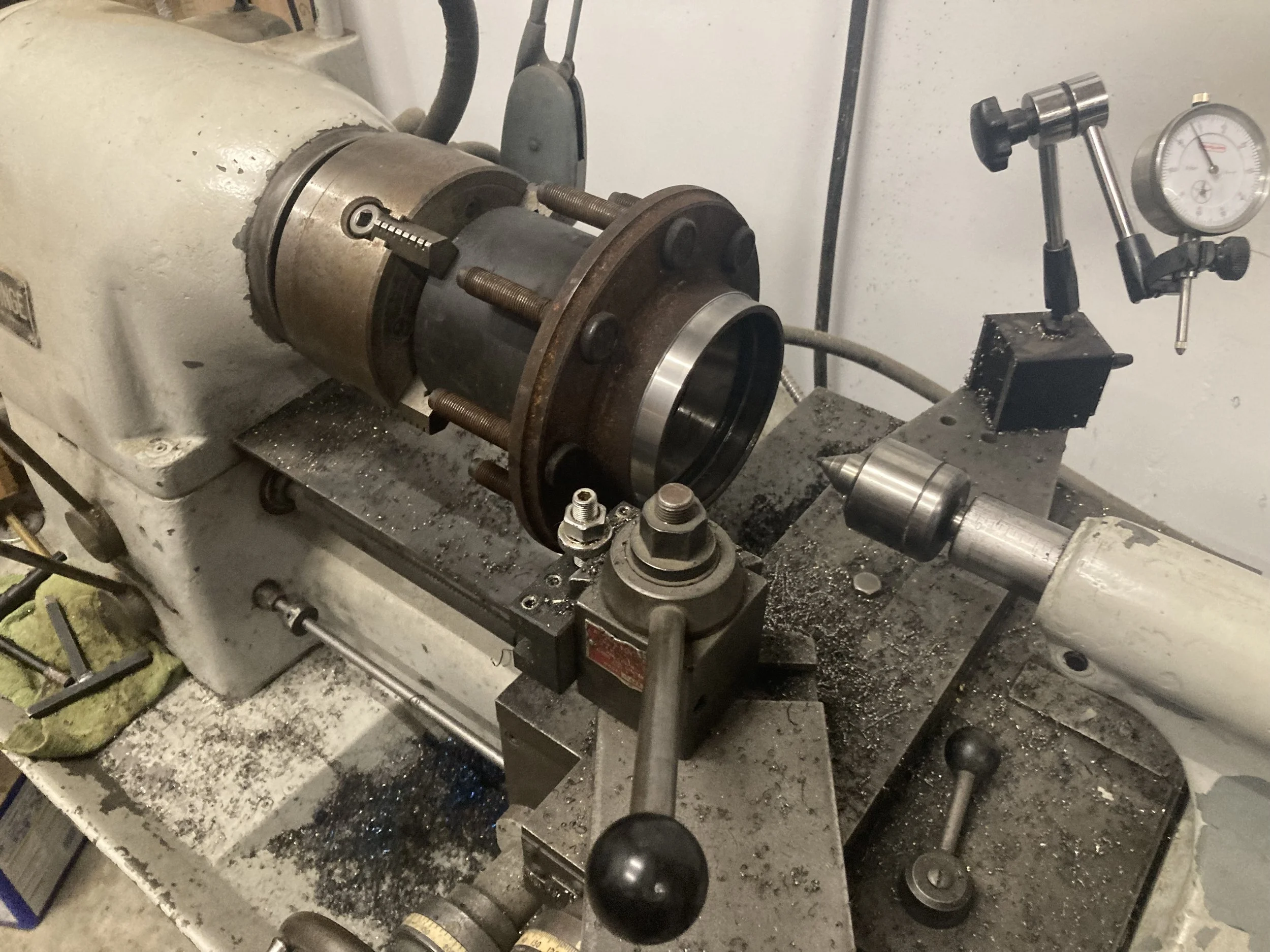

One of the biggest challenges was integrating ABS into this 40-year-old axle. To do this, we machined the hub and press-fit a 56-tooth tone ring for accurate wheel speed measurement. This modification allows us to use ABS sensors inside the rotors, making the axle safer and more reliable for modern driving conditions.

Wheel Bearing Retainers: Added Security with Stage 8 X-lock

To prevent any issues with wheel bearings, we installed Stage 8 X-lock retaining nuts on both the front and rear axles. These nuts provide a positive lock, ensuring the correct torque and preventing loosening under use. With 22 positions of locking, you can trust that your wheel bearings are torqued right and secured properly for long overland trips.

Locker: Not Necessary for Our Overland Build

We chose not to install a locker in the front axle, as our overlanding needs don’t require it. The goal of our build is to access remote destinations and get out of sticky situations, not to tackle extreme rock crawling. If we do find ourselves in a tough spot, our winch will handle the recovery, making a locker unnecessary for our setup. If our needs change we’ll install a locker.

Final Thoughts on Our DIY Dana 60 Overlanding Build

Upgrading to a Dana 60 axle was a key part of our overlanding build, and we’ve customized it to fit our specific needs. By focusing on upgrades like lockout hubs, stronger stub shafts, modern ABS integration, and precision steering, we’ve ensured that our axle is ready for anything the road or trail throws our way. For any DIY overlander looking to boost the durability and reliability of their rig, a Dana 60 is a great choice—just make sure you pick the right components for your needs.

Up Next: 10K Miles and Counting – A Full Review of Our Mods and Dana 60 Axle Upgrade

As we hit the 10,000-mile mark on our overlanding journey, it’s time to take a closer look at how all these upgrades are holding up. From the Dana 60 axle rebuild to the gear ratio changes, lockout hubs, and stub shaft upgrades, we’ll dive into the real-world performance of our build. How’s the steering holding up? Are the ABS mods delivering the reliability we hoped for? We’ll break down the pros, cons, and lessons learned from pushing our rig to its limits our limits.