2 old makes 1 new? Tearing apart two 1970’s transfer cases to rebuild one for our overland rig

Tear-down & rebuild of two 50 year old transfer cases

We bought a pair of New Process 205 (NP205) transfer cases off Facebook Marketplace after they sat outside next to a shop for years, waiting for a build that never came. When we got our hands on them, the heavily weathered exterior showed its patina after being covered in snow, pelted by rainy, and exposed to humid summers; but the inside was still full of good, clean (old), oil — free of water or debris. The shafts turned free and the shift rods moved (albeit with some effort). We knew that with the commonality of these cases we would be able to find any parts we needed, but with two, we likely wouldn’t have to source anything but consumables. We hoped 2 old would make 1 like-new transfer case for Rufus!

process & consumables used to rebuild our NP205 transfer case

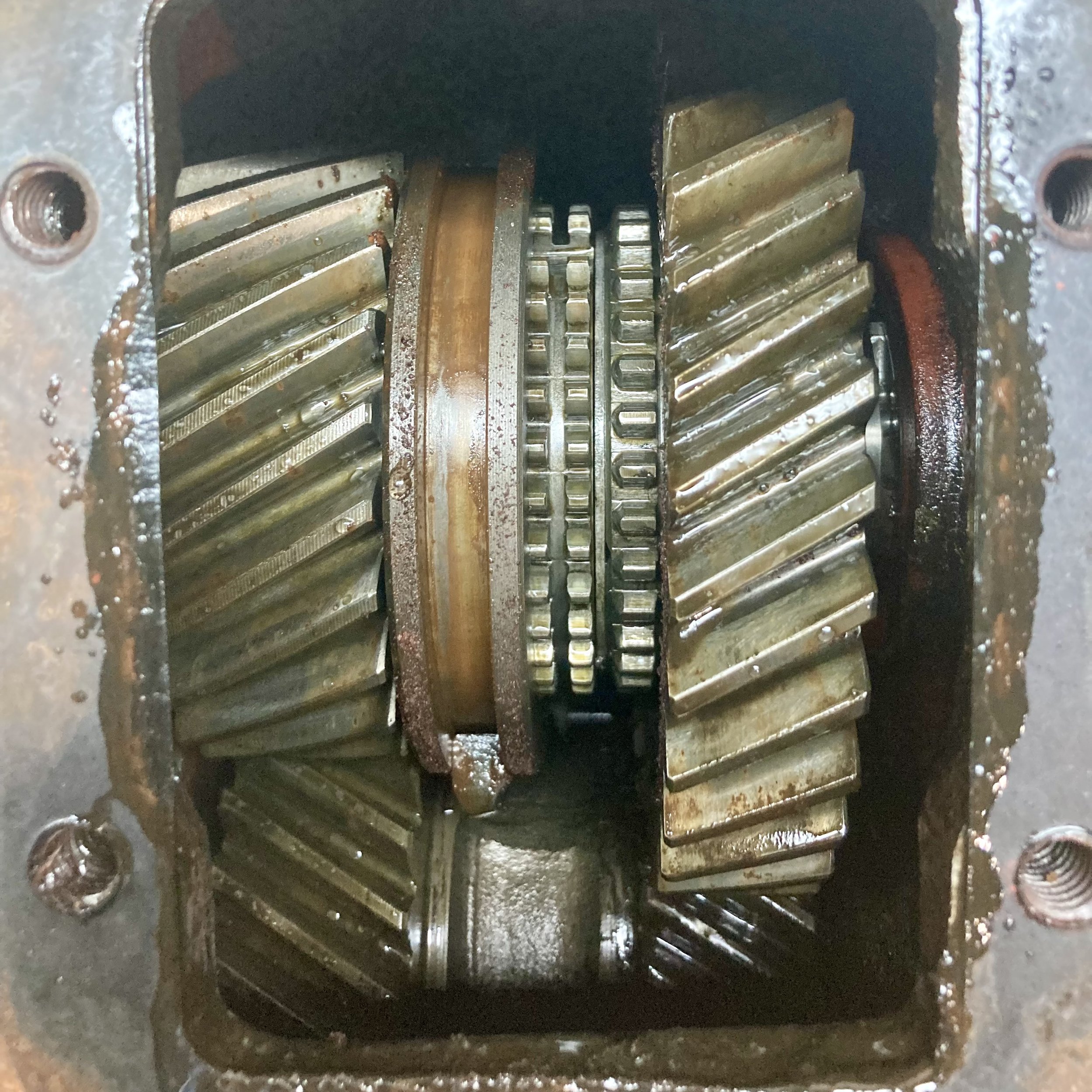

After opening the Power take off (PTO) cover of both cases, we picked the one with cleaner internals and did a full tear-down and inspection. Everything looked good, clean and tight but we decided to replace a few of the major wear components and upgrade the shift rails.

All NP205 transfer cases are made with a solid cast iron case. For us, cast iron is the best option in this situation, it’s extremely strong and will last forever. Depending on whether your NP205 is married or divorced and what vehicle it came from, the input and output shafts will be different. Our divorced unit, luckily, has the desirable and common robust 32 spline input and output shafts.

After the full tear-down, we found our transfer case to be in great shape. Bearings were tight, no excessive wear on gears or shift forks, and no signs of overheating or overuse. Even with a satisfactory inspection we decided to install new input and output bearings, idler shaft bearings, input/output seals, shift rod seals, shift rod detent springs, a set of twin stick shift rods, and topped it off with fresh 75w-140 gear oil. For the input and front output, we installed a spicer 1410 yoke and for the rear output we used a 1410 flange. We cleaned the entire case and coated the outside with farm & implement enamel paint to protect it from wear and tear.

These transfer cases are super simple. An input/rear output shaft, an intermediate shaft which shifts between high and low range, and a front output shaft. The intermediate shaft is held in place with tapered roller bearings to handle any thrust. The input and output shafts have radial ball bearings. Two shift rods move forks which can control the front and rear output independently. We have the option to run rear high or low, front high or low, or 4wd high or low. We find ourselves using rear wheel drive low almost any time we are on dirt.

We’ve been extremely happy with this transfer case. It has performed exactly as expected. With Rufus weighing in at 12,700 pounds (5760kg), our transfer case and driveline have to be robust and ready to handle our day-to-day adventures. We think with the new oil and bearings our transfer case will be ready for another 50 years of reliable service and if it needs parts we, are confident they will be available. See below for a full list (with links) of what we used to rebuild this NP205, in case you find yourself in the same position!

What we used to rebuild

TIMKEN 1307L Input bearings

TIMKEN 307L Output bearings

TIMKEN 2793 Idler shaft bearings

Valvoline 75W-140 Gear Oil

TIMKEN 2287 Shift seal

TIMKEN 473468 Output seal

Rust-Oleum farm & implement enamel paint

We found these resources invaluable during this rebuild process - ORD - NP205 and NP205 Rebuild and Info