DIY Transfer Case Mount: Custom Cross member Build for NP205 Off-Road Expedition Rig

How We Mounted a Divorced NP205 Transfer Case with a Custom Crossmember

To mount our divorced NP205 transfer case, we designed and built a custom crossmember. It had to be strong enough to handle the twisting forces of the driveline, but not so rigid that it prevented the truck frame from flexing during off-road use. At the same time, it had to precisely locate the transfer case to maintain correct driveline angles, shaft lengths, and alignment with the front differential.

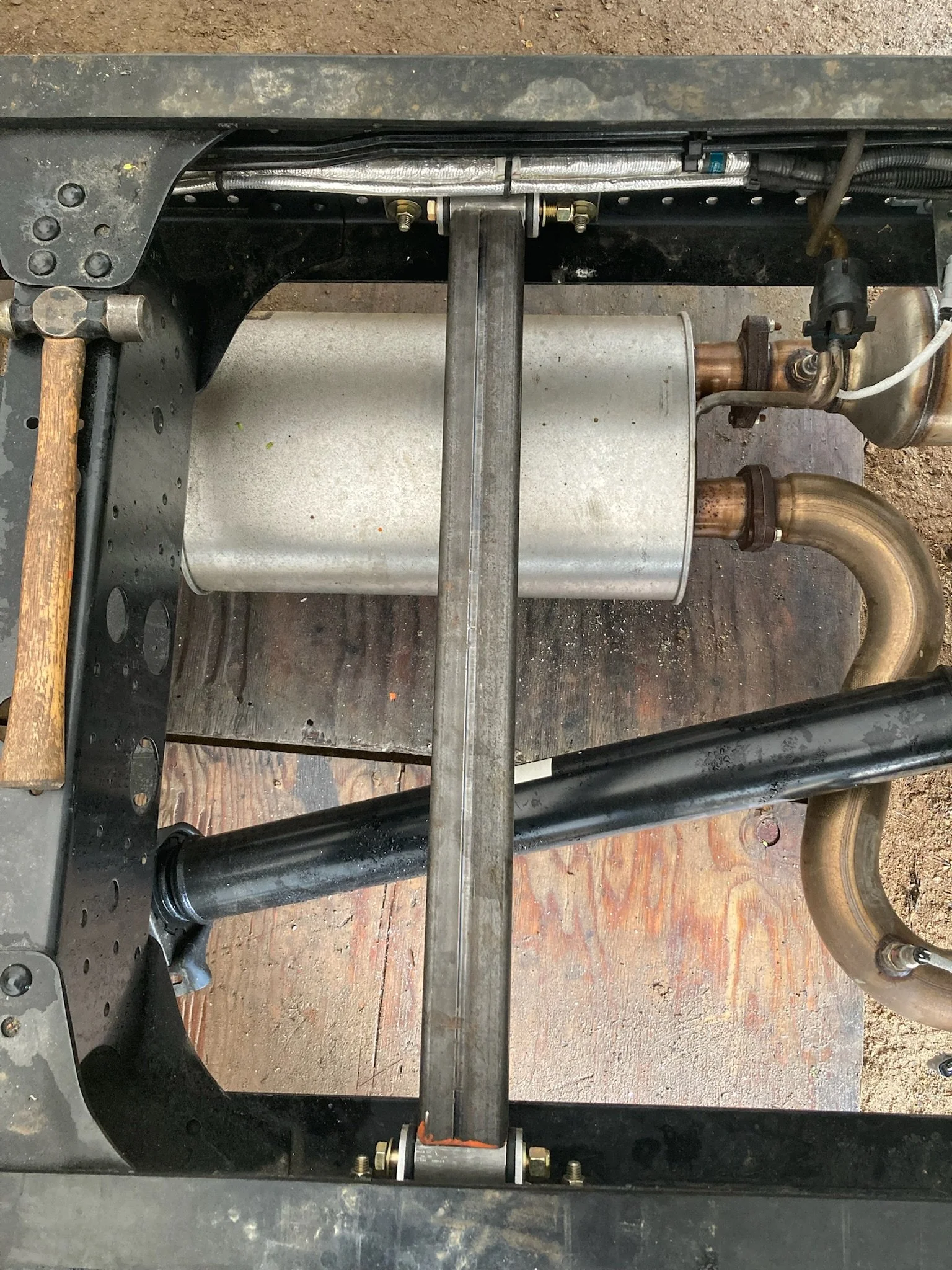

The Cross member: The Meat and Potatoes of the Mount

We started with how the cross member would attach to the frame. The goal was to keep the transfer case fixed between the frame rails, while still allowing the frame itself to twist and flex as needed. We also wanted the crossmember and mount to be completely removable — no permanent modifications to the truck frame.

To do this, we used roll cage tie-in brackets with bushings. These brackets bolt to the frame and allow us to remove the cross member with just two bolts. We attached them to ¼” steel plate and spanned the frame rails with 1.5” x 3” rectangular tubing. Using a hole-saw, we notched the tubing and welded in the bushing.

Using angle iron, we made brackets to attach the cross member to the transfer case using the factory mounting points and bolts. To help isolate vibration, we used rubber between the brackets and the case. The brackets were made extra long, giving us vertical adjustment when mating them to the cross member. At this point, the cross member could slide fore and aft, and the transfer case could move up/down and left/right — giving us full flexibility to fine-tune the fit.

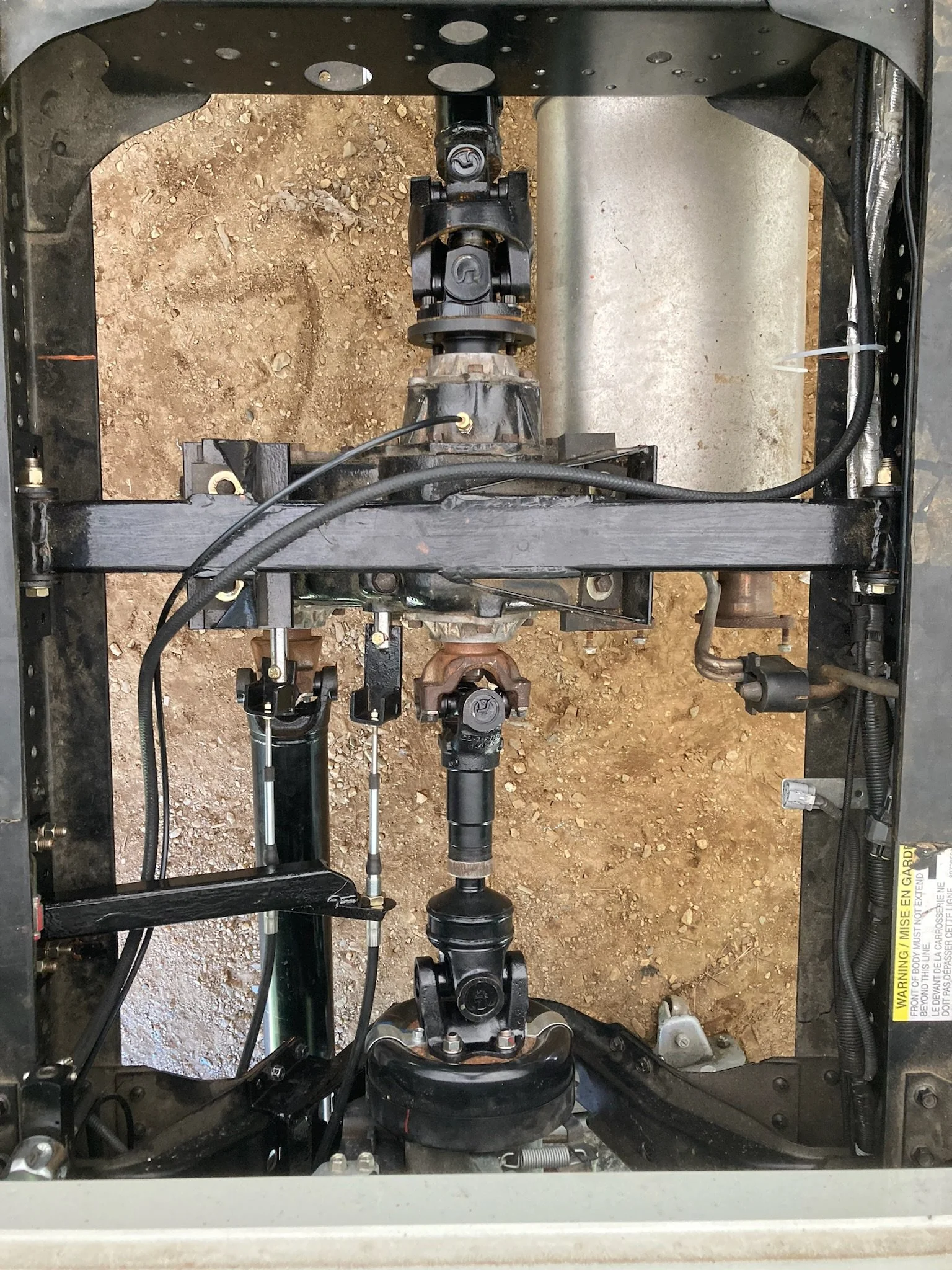

Lining Everything Up: Time to Do Some Math

The transmission has a 2.5° downward angle. Based on this, we calculated that if the transfer case was mounted 3/8" lower and 13.5" aft of the transmission output, the intermediate shaft would have opposing 1.25° u-joint angles. This alignment reduces drive line vibration and ensures proper U-Joint needle bearing lubrication.

With the transfer case positioned close to the transmission, we centered the input yoke behind the transmission by moving the transfer case side to side in small increments. Once aligned, we lowered it 3/8" and clamped it in place. Using the transmission output as a fixed reference point made this easy. Then we slid the whole cross member and transfer case assembly back 13.5", carefully checking that nothing shifted.

Front Differential Offset — Wait, What?

Next, we needed to clock (rotate) the transfer case so the front output aligned with the front differential. We used the frame rail as a reference point and measured the distance to the front diff yoke. We rotated the transfer case until the measurements matched, then clamped it in place.

We then slid the assembly back toward the transmission again to confirm the height and side-to-side alignment were still good. Once satisfied and after a few more adjustments, checks, adjustments, rechecks, we tack-welded the mount to the cross member.

Final Fit and Welding

With everything tack-welded and clamped in place, we triple-checked all the measurements. Everything was exactly where we wanted it, so we welded the cross member and mount solid. With the unit fully assembled, we re-positioned it 13.5" aft of the transmission, clamped the brackets to the frame, and used a transfer punch to mark the mounting holes.

After drilling the brackets using a drill press, we did one final test fit with everything bolted together. Satisfied with the results, we removed the crossmember and gave it a coat of paint. This custom setup should offer years of reliable service and be easy to adjust or repair if we ever need to make changes.

Lubrication: No One Likes a Hot, Dry Bearing

When clocking your NP205 to match front differential offset, don’t forget to consider oiling. The NP205 is splash-lubricated — part of the gear-train sits in oil, the spinning gears fling it where it needs to go. Clocking the case changes the vertical distance between the fill and drain holes, so you’ll want to stay within acceptable limits.

Luckily, the NP205 is very forgiving. Our setup keeps oil levels in check even when rotated, and we run synthetic 75W-140 gear oil. After long highway runs, the case is only warm to the touch — exactly what you want.