Custom ABS Retrofit: DIY Antilock Braking System Upgrade

Custom ABS Retrofit: How I Integrated Antilock Braking Into a Modified 4x4 Axle Swap

Understanding ABS and Its Function

Antilock Braking Systems (ABS) are designed to prevent wheel lockup during heavy braking or when driving on slippery surfaces. By keeping the wheels rotating, ABS, allows the driver to maintain steering control and, in many cases, shortens stopping distances.

Modern ABS technology was first introduced in cars and trucks in the 1970s but did not become widespread until the mid-1990s. A simplified ABS setup typically includes four key components: wheel speed sensors, a valve, a pump, and a controller.

Wheel speed sensors monitor the rotational speed of each individual wheel and send this data to the controller. The controller processes the information and, when needed, adjusts the valve position accordingly. Under normal conditions, the valve allows brake pressure to transfer directly from the pedal to the wheel. However, if the system detects that a wheel is decelerating faster than the others—indicating a potential lockup—the valve releases pressure to keep the wheel spinning. The pump and valves then work together to maintain maximum braking force without losing traction.

Adapting ABS to a Custom Axle Swap

In Rufus, our expedition truck, both the front and rear axles were replaced during a 4x4 conversion. Unfortunately, neither of the new axles included ABS provisions that matched the factory setup.

The front GM Dana 60 axle did not have ABS from the factory.

The rear Dodge Dana 80 axle included a 120-tooth tone ring mounted on the ring gear.

The original system used 56-tooth tone rings in each hub, allowing all four wheel speeds to be individually monitored.

To restore ABS compatibility, I needed to fabricate new tone rings and sensor mounts that matched the factory signal parameters.

Rear Axle Solution

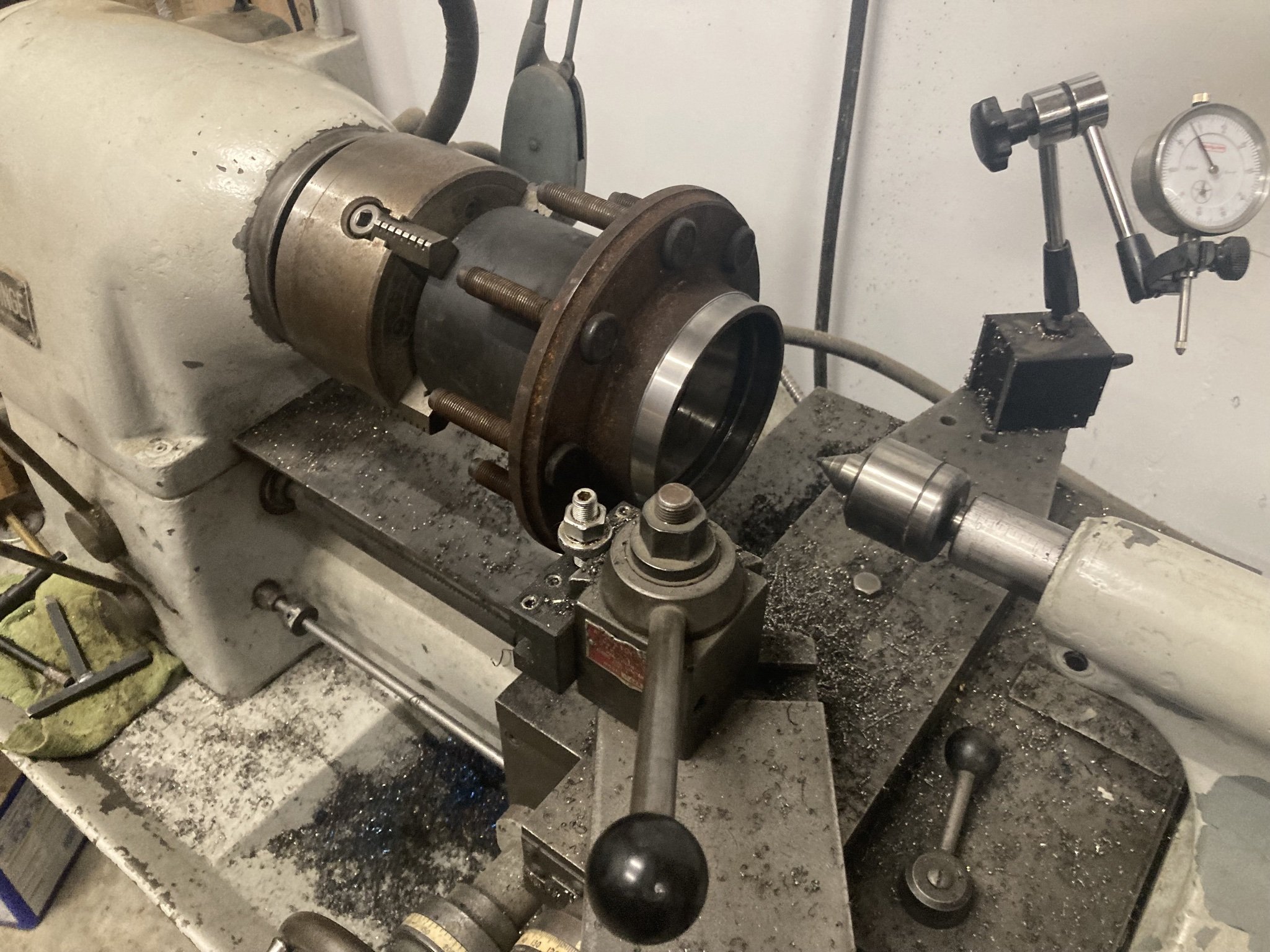

For the rear axle, I designed and cut a 56-tooth tone ring from ½-inch mild steel using a water jet. After carefully measuring the hub and brake drum clearance, I machined the hub and tone ring to achieve a precise interference fit. The tone ring teeth were made tall enough for the sensor to read from the side.

Once installed, I fabricated a custom sensor mount using angle iron, positioning the sensor close—but not too close—to the tone ring. With the system assembled, I used a scan tool to verify that each wheel speed sensor was reading correctly.

Front Axle Solution

The front axle presented more challenges. After measuring the hub, I created another 56-tooth tone ring and machined it to fit with the same interference method. Unlike the rear, the front sensors needed to read from above the tone ring rather than the side.

However, the front axle’s knuckle pivots for steering, and with the factory 12.3-inch disc brakes, there wasn’t enough clearance to fabricate a sensor bracket and fit the sensor inside the rotor. To solve this, I extended the sensor wires and mounted the front sensors near the rear ones, where there was ample space.

This setup “tricks” the ABS controller into reading identical wheel speeds front and rear. While this means the computer cannot prevent front-wheel lockup, it’s a compromise I’m comfortable with. Having grown up driving non-ABS vehicles, I understand the braking characteristics and limitations. In the future, I plan to upgrade to larger brakes, which should provide enough room to install the sensors directly in the front hubs.

Performance and Results

After 10,000 miles of driving—through sand, snow, rain, dirt, and mud—the ABS modification has proven reliable. The truck’s braking performance, speedometer, and cruise control function as intended, with no warning lights or error codes. Despite the unconventional sensor placement, the vehicle remains stable and predictable under all driving conditions.

Conclusion: Practical Engineering and Personal Responsibility

This custom ABS retrofit demonstrates that with careful measurement, fabrication, and understanding of brake system dynamics, it’s possible to adapt modern safety systems to heavily modified vehicles. However, any vehicle modification—especially those involving braking systems—may fall outside local or federal regulations and carries inherent risk. Always do your own research, understand the implications, and make modifications you are personally comfortable with.

For now, this solution works perfectly for Rufus. Future brake upgrades may allow for a more traditional ABS sensor layout, but as it stands, the system performs safely and effectively for our needs.