Custom Leaf Springs for 4x4 Builds: Selection, Modifications, and Expert Tips

Why We Stuck With Leaf Springs: Styles, Considerations, and What We Learned

When it came time to build Rufus, our trusty DIY 4x4 expedition truck, we knew we’d be keeping the tried-and-true leaf spring suspension system. While there are plenty of modern suspension options, the simplicity, durability, and reliability of leaf springs made them a perfect fit for our build. In this post, we’ll dive into the different types of leaf springs in Rufus, why we chose to stick with them, and what you need to know to order and modify them for your own project.

Factory Leaf Springs: What We Started With

Rufus originally came with a leaf spring suspension. The front I-beam axle was supported by a set of mono-tapered leaf springs, while the rear axle was equipped with a multi-leaf spring pack and an overload spring for extra heavy loads.

A tapered leaf spring is thickest at the center, where it attaches to the axle, and tapers down toward the ends. This unique taper creates a variable spring rate. As the spring compresses under load, its resistance to further compression increases, providing a softer ride when unloaded and a stiffer ride when carrying weight.

On the other hand, the multi-leaf spring pack consists of progressively shorter leaves stacked and bolted together, with the longest leaf attached to the axle in the center and at each end to the frame by a bushing and shackle. The design of the pack is intended to support a consistent load, there fore it isn’t ideal for varying weights. Given our build's need for a steady, predictable load distribution, we found that the multi-leaf design worked perfectly for us.

Understanding Leaf Spring Specifications: What You Need to Know

When considering leaf springs for your project, several critical factors must be accounted for. While some dimensions are determined by the factory design, others can be customized to suit your build’s specific needs. Key variables include:

Width

Eye-to-eye length

Center Pin location

Bushing size

Load rating

Arch or curve of the spring

For Rufus, we made adjustments to several of these factors, including eye-to-eye length, pin location, load rating, and the overall length of the springs.

Custom Springs: Finding the Right Manufacturer

From the outset of our build, we knew we’d need a set of custom leaf springs to match our specific requirements. Leaf springs are a common suspension component, and finding a shop capable of producing custom springs isn’t too difficult—at least, it shouldn’t be. Unfortunately, after contacting at least 10 local shops, we hit a wall. Either the shops didn’t have the necessary expertise or they were too busy to take on such a custom job.

That’s when we found Alcan Spring in Grand Junction, Colorado. They were more than willing to take on the challenge, and their work was exceptional. They guided us through the process of taking precise measurements, ensuring we received exactly what we needed for our build.

The Ordering Process: What We Measured and How We Estimated Weight

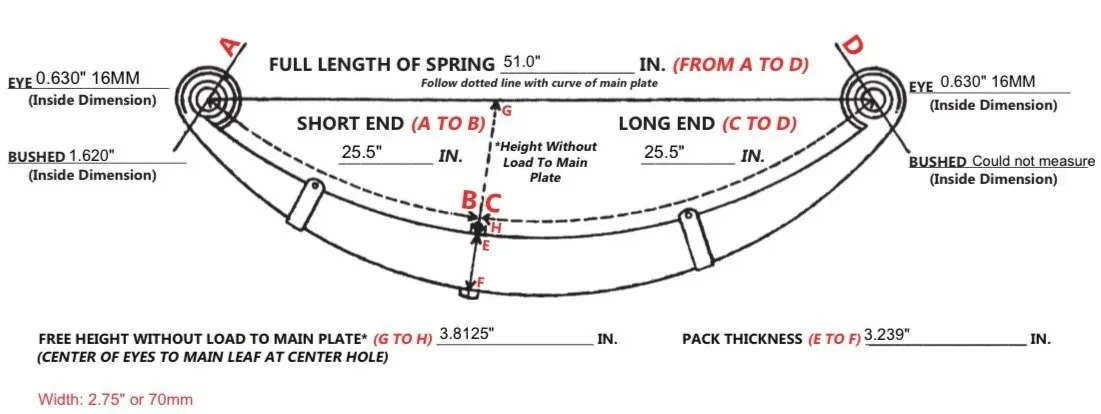

To place our order with Alcan, we needed to provide detailed measurements of the factory springs. Their worksheet required us to supply data like:

Length

Width

Center pin location

Bushing size

Pin size

Leaf thickness

Pack thickness

But there was one challenge: our truck was in the middle of a 4WD conversion, so we couldn’t drive it to a scale to get an accurate weight. To overcome this, we came up with a creative solution.

We used a hydraulic bottle jack and modified it by drilling a hole in the high-pressure section to install a pressure gauge. By knowing the piston size and measuring the pressure, we could estimate the weight based on the area of the piston. This gave us a rough estimate of the weight, although the build wasn’t complete.

For the front axle, we weighed the partial build at around 4,200 pounds and estimated an additional 1,200 pounds, giving us a total axle weight of about 5,400 pounds. The rear axle was more difficult, as the camper box wasn’t assembled yet, but we based our spring load on the maximum rated tire weight of 7,700 pounds—the total weight of the finished build came in at about 7,200 pounds for the rear and 5,000 pounds for the front.

Spring Modifications: Lift, Arch, and Customizations

Alcan added custom arch to the springs to account for the lift required by our 4x4 swap. They arched the front springs by 2 inches and the rear by 3.75 inches, which not only leveled the truck but also provided the necessary clearance for our 35” tires.

One of the challenges with modifying spring arch is that it shortens the eye-to-eye distance, which in turn affects the shackle angle. To maintain proper function, the shackle angle must remain between 5° and 10°. To compensate for the change in distance, Alcan carefully adjusted the length of the springs to maintain the correct eye-to-eye measurement.

Another custom modification we requested was to move the rear axle back by one inch. This increased the truck’s wheelbase from 150 inches to 151 inches, which provided just enough space to accommodate our camper’s entry stairs. The factory rear axle had been centered on the spring, but with this modification, Alcan shifted the pin one inch aft.

The End Result: A Perfect Fit

Now, after completing the build and driving 10,000 miles on the custom springs, we couldn’t be happier with the results. The springs handle the weight perfectly, and the ride quality is solid both on the road and off. The truck weighs in at over 12,000 pounds, yet we don’t feel the need for sway bars, thanks to the performance of these custom leaf springs.

Our experience with Alcan Spring was flawless. They provided expert advice, excellent craftsmanship, and delivered exactly what we needed. If you’re in the market for custom leaf springs, I can’t recommend them enough!