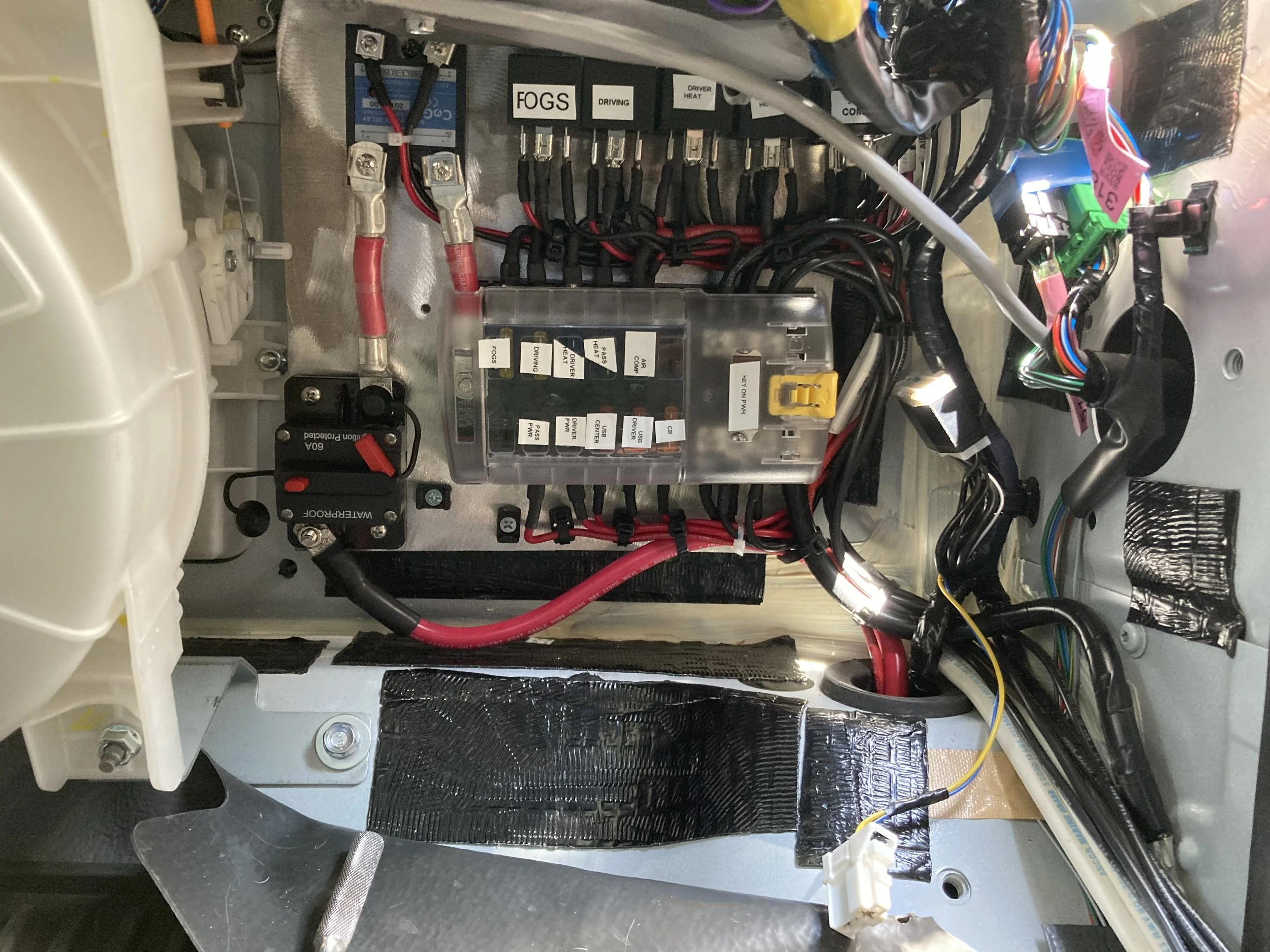

Overland Truck 12V Power Distribution System - InCab Electrical Upgrade

How I built a reliable in-cab 12V power distribution system for an overland truck using an ignition-switched relay, a 12v fuse block, and dedicated auxiliary wiring.

Rufus started life as a bare‑bones commercial truck, with very few in‑cab amenities beyond the essentials. From the factory, the cab was equipped with power windows, a single 12V outlet, and a USB port tied to the radio for auxiliary input. That was it. Knowing we would be spending long hours in the driver and passenger seats, we wanted to significantly improve comfort and functionality.

Those upgrades, however, come with a cost: electrical load. In an overland truck, electrical reliability directly affects comfort, safety, and self‑sufficiency—especially when traveling far from support. The factory electrical system was never designed to support multiple accessories running simultaneously, and relying on the original circuits would risk voltage drops, nuisance faults, or a dead battery. To address this properly, we designed a dedicated in‑cab 12V power distribution system built for reliability, expandability, and safe operation.

Design Approach

When I design electrical systems for overland and expedition vehicles, I focus on four principles: reliability, isolation from factory wiring, parts/component availability, and room for future expansion. This system was built from the start to support real‑world travel, not just accessories bolted on as an afterthought.

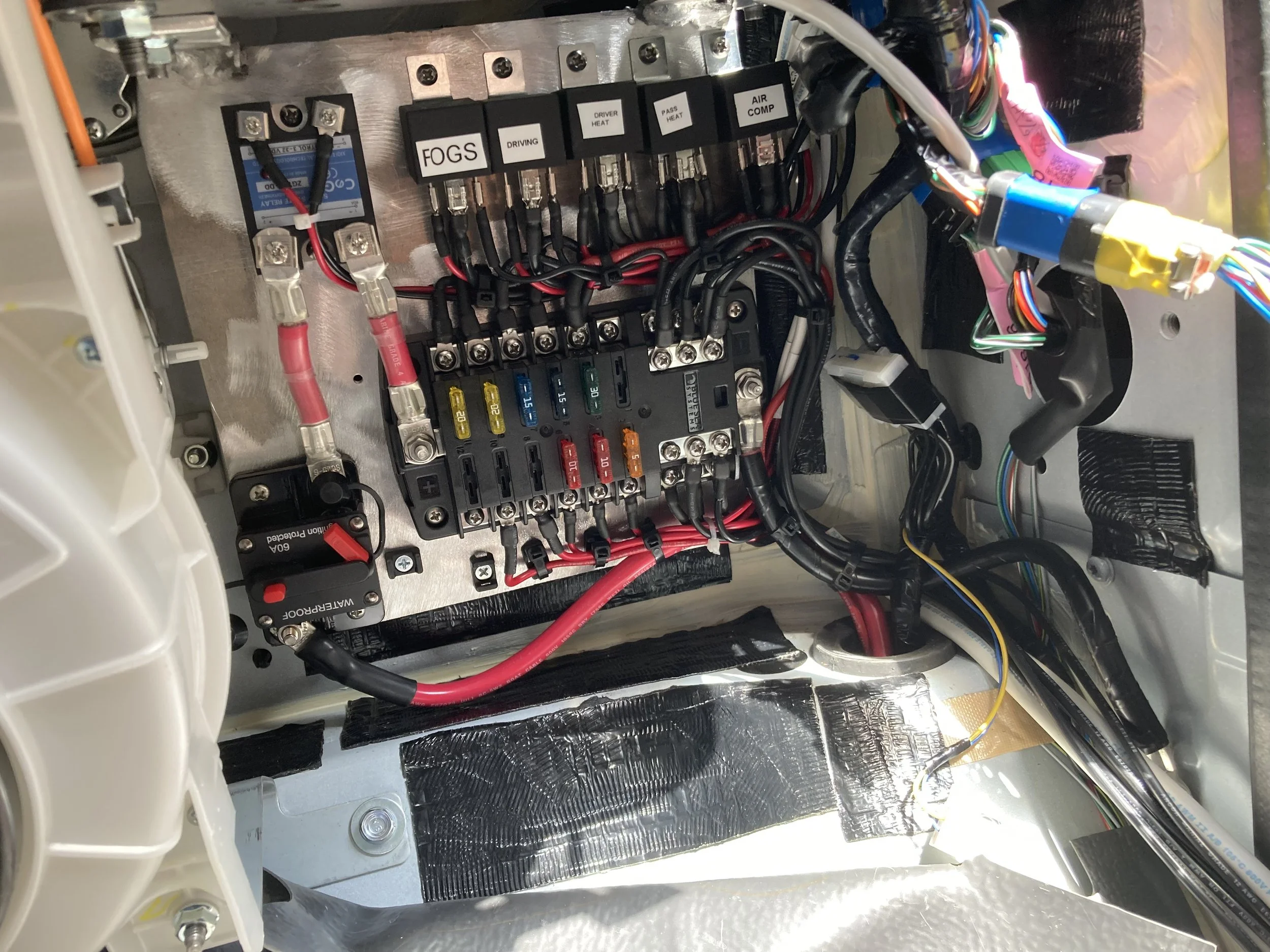

Rufus’ solution was to install a dedicated 12V distribution panel powered directly from the start battery. Power is supplied through a solid‑state relay that is triggered by the ignition key in the ON position. This ensures the entire panel is only energized when the truck is running, eliminating any risk of parasitic draw while parked.

This architecture allows us to support higher electrical loads while maintaining complete isolation from the factory wiring. It also provides a clean, centralized point for fusing and future expansion.

Electrical Loads

The distribution panel supports a wide range of in‑cab and auxiliary accessories, including:

Heated and power seats sourced from a 2019 Volvo XC90 (covered in detail in a future post)

Fog and auxiliary driving lights

Multiple high‑output USB power ports

CB radio

Low‑current accessories such as USB power, the CB radio, and the camera mirror are powered directly from the fused 12V distribution block. Higher‑current loads—including the seats, lighting, and air compressor—are controlled through individual relays and switched circuits for added safety and load management.

Wiring and Installation

Power is delivered to the system via Anchor 4‑AWG marine wire run directly from the battery to the solid‑state relay, and then to a Blue Sea Systems 12V distribution block. Ignition‑switched power for the relay trigger was sourced from an existing key‑on circuit under the dash.

Each accessory circuit is individually fused at the distribution block, with several spare fuse positions reserved for future upgrades. This provides both protection and flexibility as the electrical system evolves.

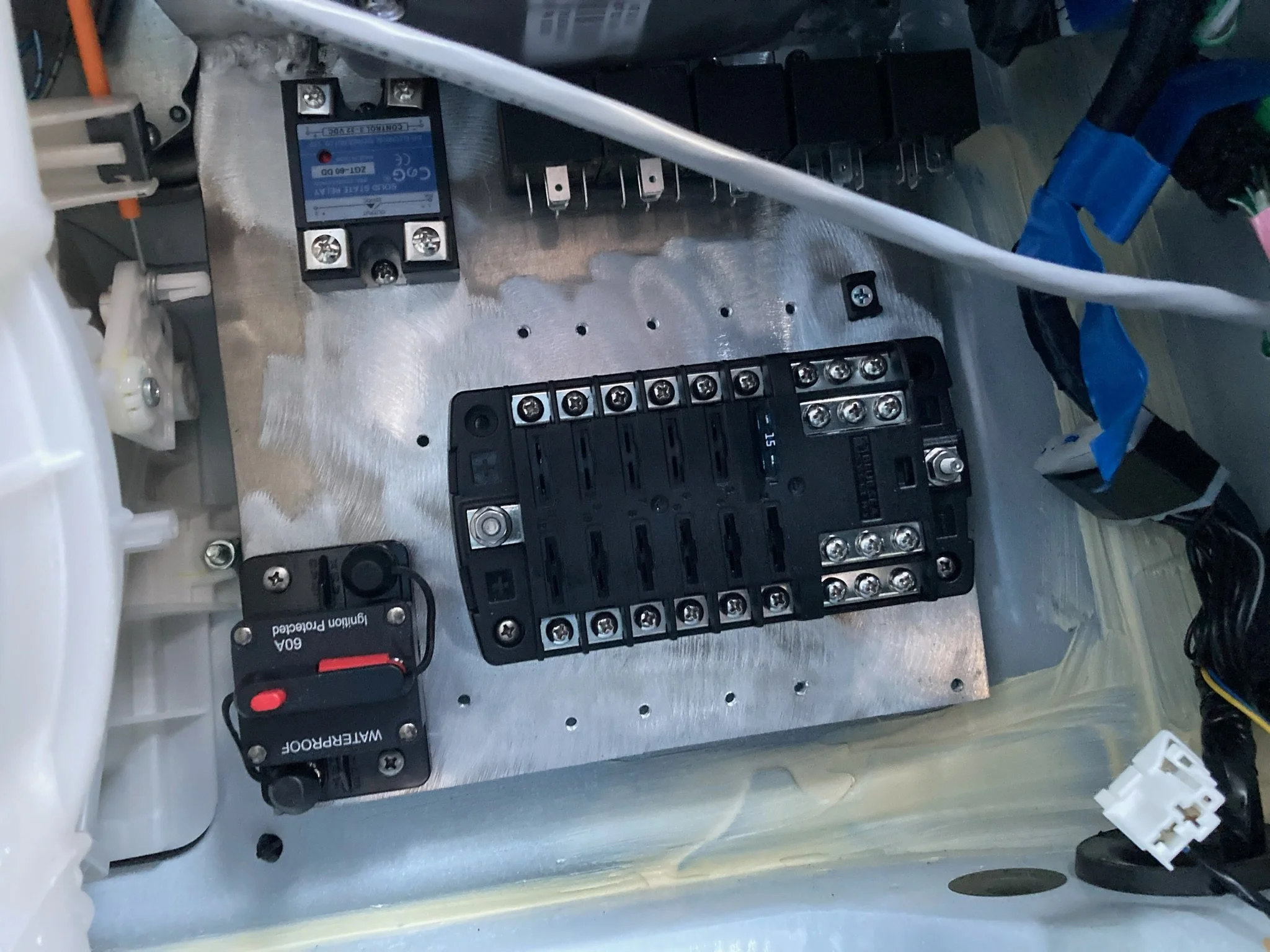

The distribution block and relays are mounted to a custom aluminum backing plate and installed under the passenger‑side dashboard. This location keeps the components protected and out of the way, while remaining fully accessible for inspection, service, or expansion. Adding additional circuits—whether for more lighting or a second on‑board air compressor—can be done quickly without reworking the system.

Why This Matters for Overland Travel

In a dedicated overland or expedition truck, systems like lighting, communications, on board air, and adjustable seat comfort are not luxuries—they are part of the vehicle’s operational capability. A centralized, ignition‑switched 12V power distribution system reduces failure points, simplifies troubleshooting, and ensures the truck behaves predictably in remote environments.

By separating auxiliary loads from the factory electrical system, I can confidently add capability without compromising reliability.

Results

This dedicated 12V power distribution setup provides stable, reliable power to all in‑cab accessories without compromising the factory electrical system or risking battery drain. Because the panel is only energized with the ignition on, it aligns perfectly with how the truck is used: power when driving, zero draw when parked.

Just as importantly, the system was designed with future modifications in mind. As Rufus continues to evolve, the in‑cab electrical infrastructure is already in place to support whatever comes next.

Key Components

Anchor Marine Wire 4‑AWG primary power cable from start battery

Individually fused branch circuits

Aluminum mounting plate

Automotive relays, switches, and circuit protection